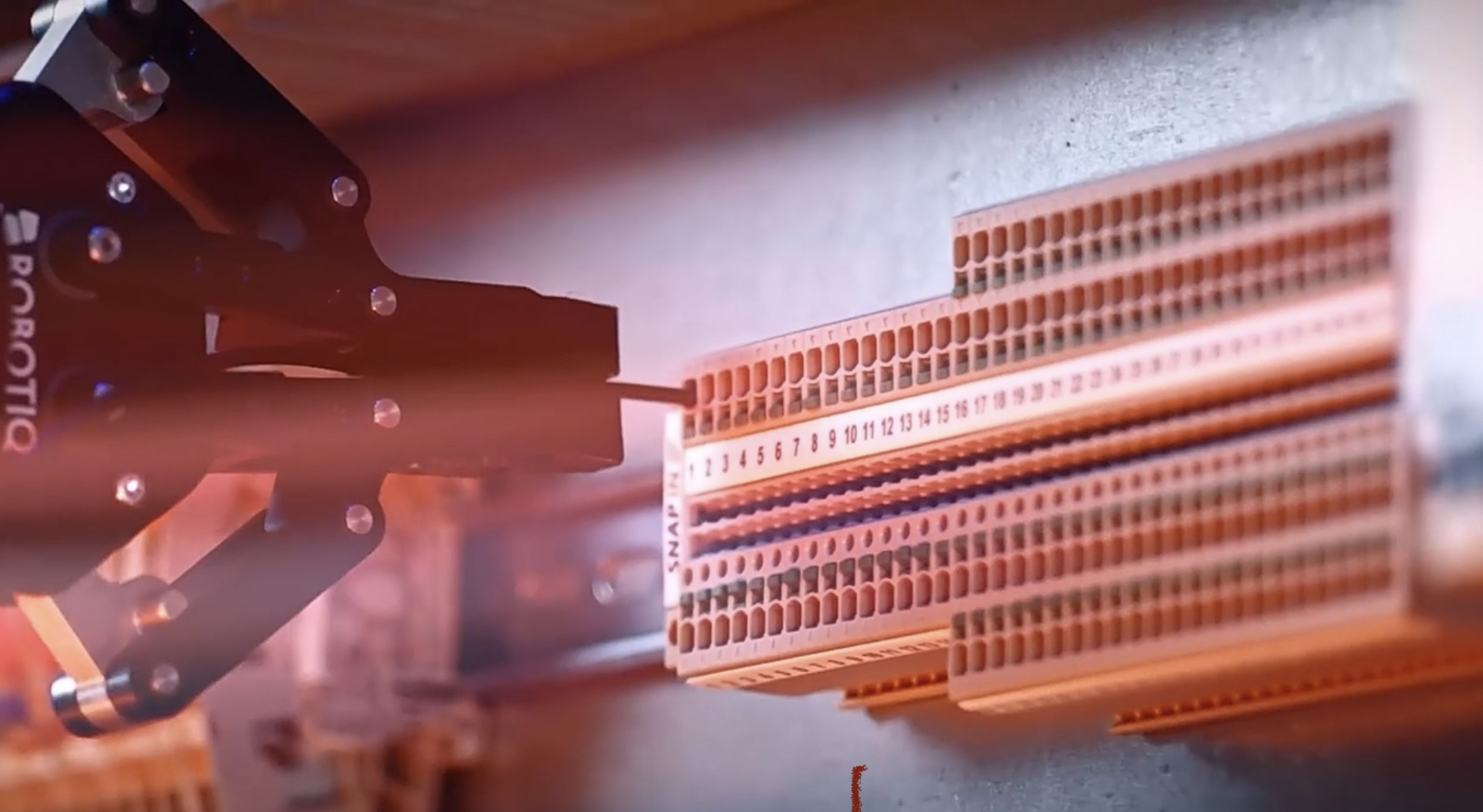

SNAP IN

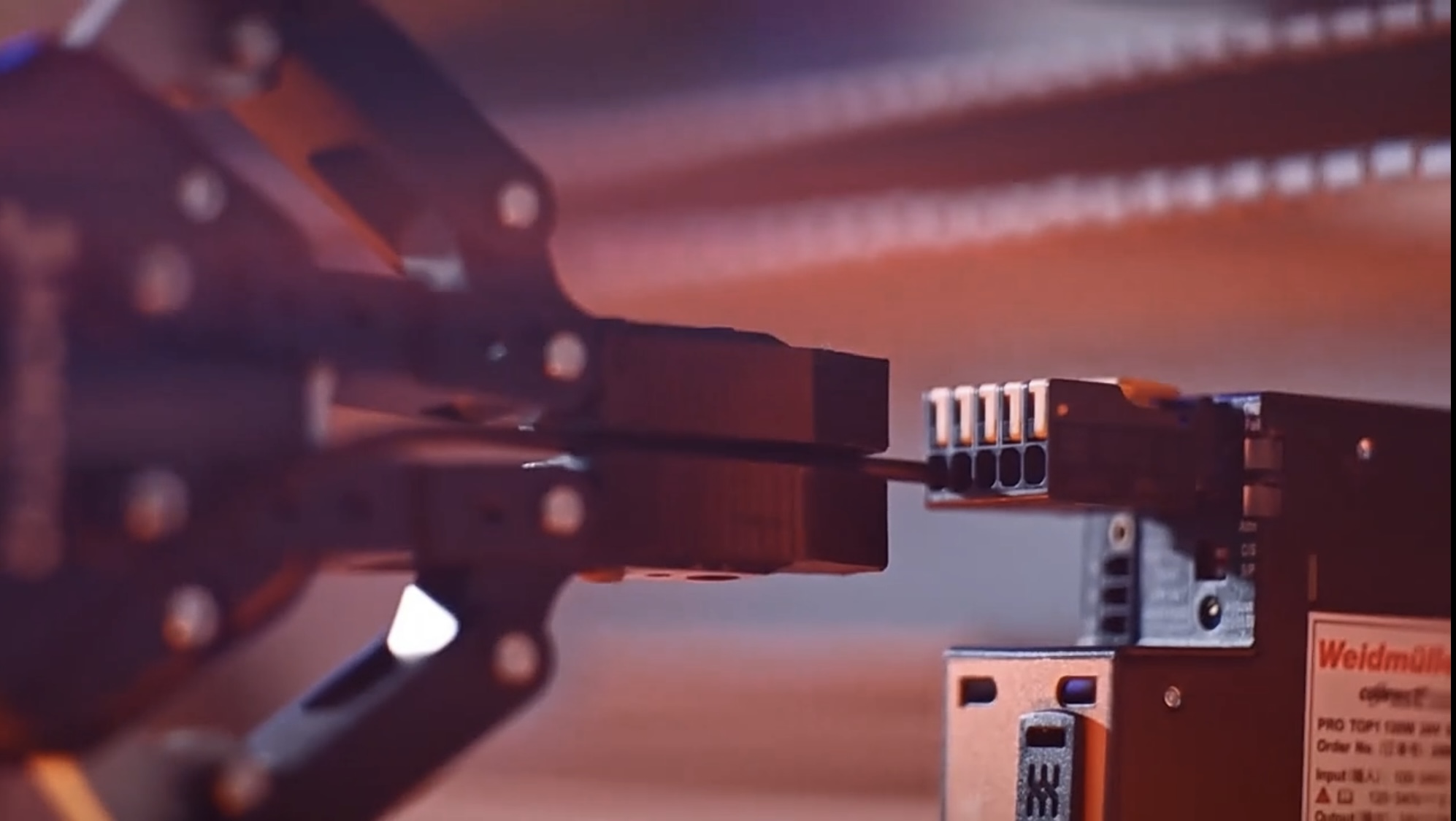

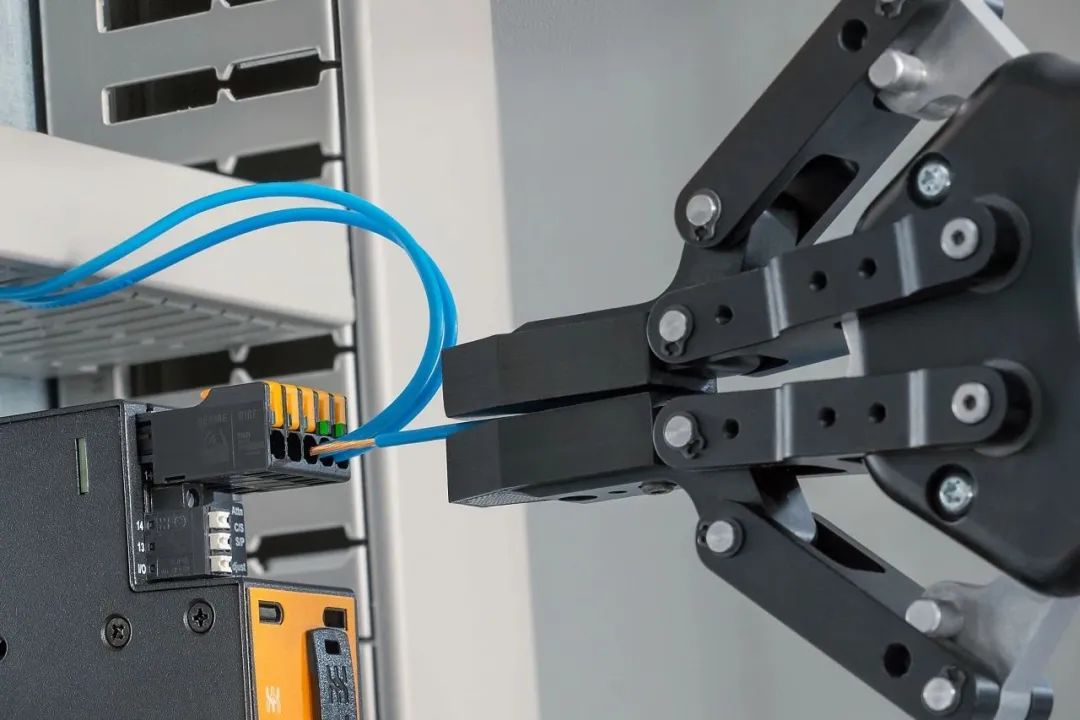

Weidmuller, the global industrial connection expert, launched innovative connection technology - SNAP IN in 2021. This technology has become a new standard in the connection field and is also optimized for future panel manufacturing. SNAP IN enables automatic wiring of industrial robots

Automation and robot-assisted wiring will be key to future panel manufacturing

Weidmuller adopts SNAP IN connection technology

For many terminal blocks and PCB connectors

PCB terminals and heavy-duty connectors

Optimized

Automated wiring adapted to the future

SNAP IN provides an audible and visual signal when a conductor has been successfully inserted – essential for future automated wiring

In addition to its technical advantages, SNAP IN offers a short, cost-effective and process-reliable solution for automated wiring. The technology is extremely flexible and can be adapted to different products and panels at any time.

All Weidmuller products equipped with SNAP IN connection technology are delivered to the customer fully wired. This means that the product’s clamping points are always open when it arrives at the customer’s site – no need for time-consuming opening thanks to the product’s anti-vibration design.

Fast, easy, safe and adaptable to robotic operation:

SNAP IN is ready for automated production processes.

Post time: Feb-02-2024