The trend of going global is in full swing, and more and more energy storage companies are participating in international market cooperation. The technical competitiveness of energy storage systems is becoming more and more important.

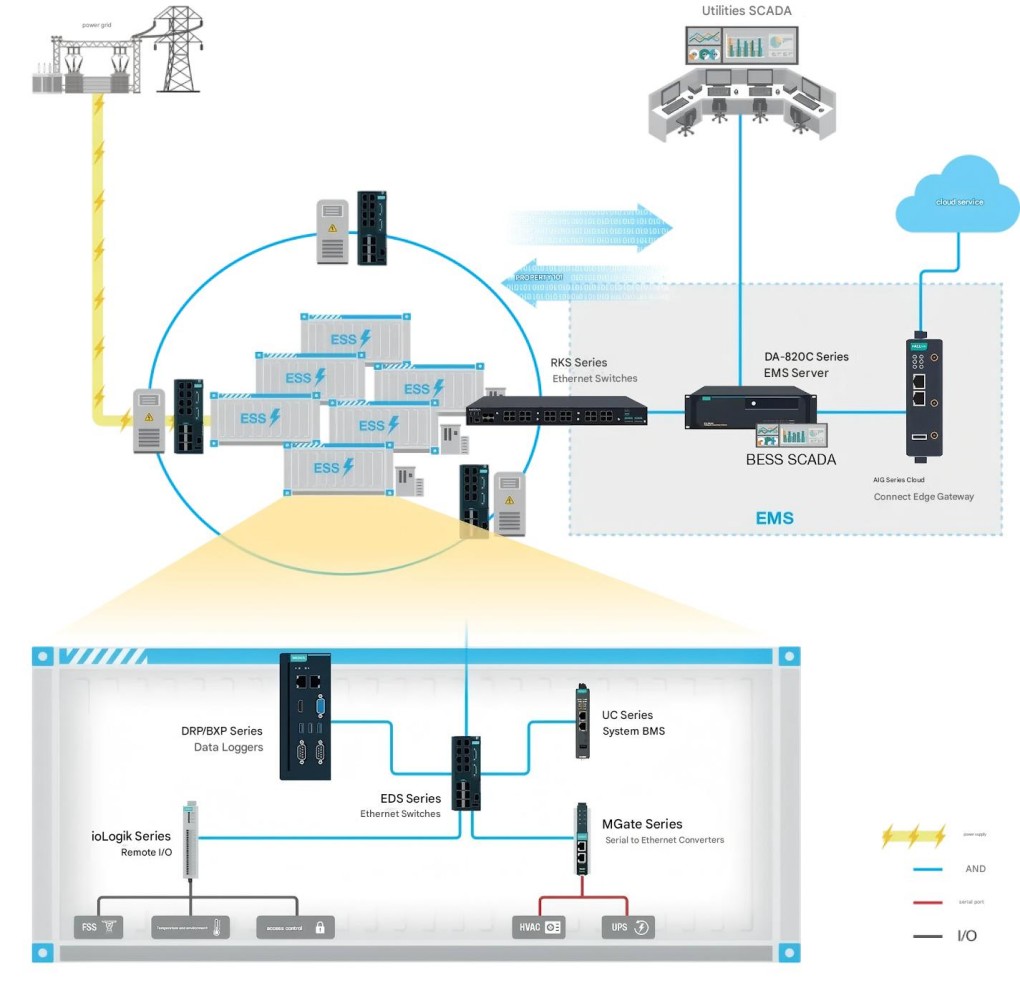

Battery management systems (BMS) and energy management systems (EMS) are deployed in energy storage cabinets and large-scale megawatt energy storage sites to play a real-time monitoring role. Collecting and utilizing data from various systems is the basis for the efficient operation of BMS/EMS.

To ensure the continuous and stable operation of battery energy storage systems (BESS):

Owners usually sign decades-long contracts with battery suppliers, covering terms such as rated capacity and performance guarantees.

Battery suppliers will also formulate battery usage rules to regulate specific operations.

For example -

Battery module health status (SoH) below 60%~65% is not covered by warranty

Battery and auxiliary system data, BESS owners must properly store and submit to suppliers when warranty claims are made

Tens of thousands of battery data, collecting state of charge (SOC), SoH, temperature, voltage, current, etc.

Number of auxiliary systems in energy storage cabinets, stored for at least one year

These rules are challenging energy storage systems.

System Requirements

Challenges in operating and maintaining energy storage systems include the need to store large amounts of data locally, as well as pre-process and upload data to the cloud.

[Manage Assets]

Preventive maintenance can be performed through cloud-based big data analysis to reduce the risk of failure. To this end, plug-and-play edge gateway devices need to be deployed to quickly transmit field data to the cloud platform.

[Record Data]

Use data loggers to store local data, preserve complete data assets, and solve data insufficiency and missing problems.

[Use Industrial-Grade Devices]

Since BESS sites are often located in remote or coastal areas with harsh environments, it is critical to select computers and network communication devices that support wide temperature operation, are resistant to electromagnetic interference, or have anti-corrosion coatings.

"Why Moxa"

In response to the needs of asset management applications, Moxa provides the AIG-302 series of plug-and-play gateway devices that can quickly transmit field Modbus data to mainstream cloud platforms such as Azure and AWS through the MQTT protocol and simple GUI configuration.

The AIG-302 series provides a development environment that allows you to programmatically convert raw data into useful information, reducing bandwidth usage and cloud computing load when uploading data to the cloud.

When transmitting data to the cloud, the gateway can enable the store-and-forward function to protect data integrity, prevent data loss, and ensure accurate data analysis

Moxa's DRP-C100 series and BXP-C100 series data loggers are high-performance, adaptable, and durable. Both x86 computers come with a 3-year warranty and a 10-year product life commitment, as well as comprehensive after-sales support in more than 100 countries around the world.

Moxa is committed to providing high-quality, durable products to meet customer needs.

New product introduction

Cloud Connect Edge Gateway-AIG-302 Series

Rely on intuitive GUI to complete configuration and easily transfer Modbus data to the cloud platform

No-code/low-code edge computing crash-proof file system provides powerful data protection and system reliability

Supports storage and forwarding functions to ensure data integrity Supports -40~70°C wide temperature operation

LTE Cat.4 US, EU, APAC models are available

Post time: Feb-13-2025