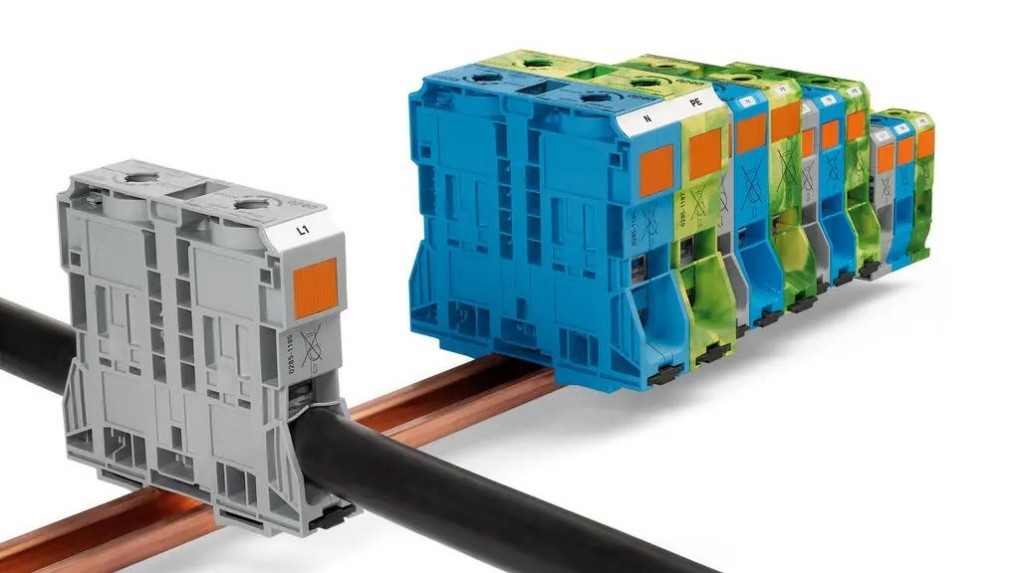

In industrial manufacturing, hydroforming equipment, with its unique process advantages, plays a key role in high-end manufacturing applications such as automotive and aerospace. The stability and safety of its power supply and distribution systems are crucial to the smooth operation of the entire production process. As a core component in this critical link, WAGO's high-current rail-mount terminal blocks (285 Series) offer superior performance, making them the preferred choice for many equipment manufacturers to enhance their competitiveness.

1. Fast Wiring

Faced with fierce market competition, equipment installation and maintenance efficiency directly impacts equipment manufacturers' production costs and profitability. WAGO's high-current rail-mount terminal blocks utilize a powerful spring-loaded POWER CAGE CLAMP terminal block, breaking with traditional wiring methods and providing just the right clamping force for equipment connections.

2. High Load Current

The drive units of hydroforming equipment are incredibly powerful, and the power distribution system must handle enormous currents. WAGO's high-current rail-mount terminal blocks are designed for demanding applications, carrying currents up to 232A, with select models reaching 353A, fully meeting the stringent requirements of high-power equipment.

3. Global Certifications

For equipment manufacturers targeting the global market, international component certification is essential for access to key markets. WAGO's high-current rail-mount terminal blocks have received numerous international certifications, including ATEX, UL, CE, CCC, and classification society certifications.

4. Why Choose WAGO

In summary, using WAGO's high-current rail-mount terminal blocks for power access and distribution in hydroforming equipment is more than just a component choice; it's a valuable investment that enhances the equipment's overall competitiveness:

For equipment manufacturers, it means faster assembly efficiency, higher product reliability, and smoother global market access;

For end users, it means less risk of downtime, lower maintenance costs, and longer equipment life.

WAGO provides trusted solutions for industrial connectivity with innovative technology, rigorous manufacturing, and superior quality.

Post time: Oct-24-2025