WAGO recently launched the 8000 series of industrial-grade IO-Link slave modules (IP67 IO-Link HUB), which are cost-effective, compact, lightweight, and easy to install. They are the best choice for signal transmission of intelligent digital devices.

IO-Link digital communication technology breaks through the limitations of traditional industrial automation and realizes bidirectional data exchange between industrial equipment and control systems. It has also become an important technology in industrial intelligent manufacturing. With IO-Link, customers can be provided with comprehensive diagnostic and predictive maintenance functions, reduce downtime, and pave the way for fast, flexible and efficient production.

WAGO has a wide range of I/O system modules to achieve automation inside and outside the control cabinet, such as flexible IP20 and IP67 remote I/O system modules suitable for a variety of applications and environments; for example, WAGO IO-Link master modules (WAGO I/O System Field) have an IP67 protection level and support a variety of functions, which can easily integrate IO-Link devices into the control environment, reduce costs, shorten commissioning time and improve productivity.

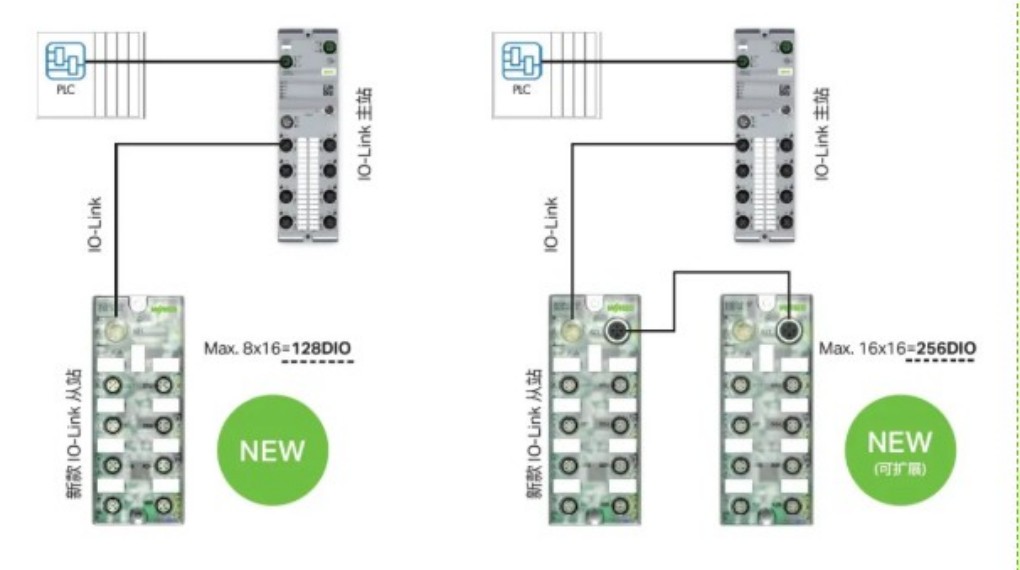

In order to better receive and transmit data between the execution layer and the upper controller, WAGO IP67 IO-Link slave can cooperate with the IO-Link master to connect traditional devices (sensors or actuators) without IO-Link protocol to achieve bidirectional data transmission.

WAGO IP67 IO-Link 8000 series

The module is designed as a Class A hub with 16 digital inputs/outputs. The appearance design is simple, intuitive, cost-effective, and the LED indicator can more quickly identify the module status and input/output signal status, and control digital field devices (such as actuators) and record digital signals (such as sensors) sent or received by the upper IO-Link master.

WAGO IP67 IO-Link HUB (8000 series) can provide standard and expandable products (8000-099/000-463x), which is particularly suitable for workstations that need to collect a large number of digital signal points. For example, lithium battery manufacturing, automobile manufacturing, pharmaceutical equipment, logistics equipment and machine tools. The 8000 series extended product type can provide up to 256 DIO points, helping customers achieve cost savings and system flexibility.

WAGO's new economical IP67 IO-Link slave is standard and universal, reduces costs and increases efficiency, simplifies wiring, and provides real-time data transmission. Its management and monitoring functions enable predictive maintenance of smart devices, making troubleshooting easier.

Post time: Nov-28-2024